Stainless steel is stain-less, not stain-proof: rust usually shows up when the protective chromium-oxide layer is compromised or when “free iron” contamination (tiny iron particles from steel wool, tools, or dirty water) sits on the surface and oxidizes. That’s why good rust removal is really about (1) removing the rust/iron contamination and (2) letting the surface re-passivate. (See the British Stainless Steel Association’s overview of how stainless steel self-passivates and passivation discussions noting free-iron contamination from fabrication.)

What to avoid (this prevents most permanent damage)

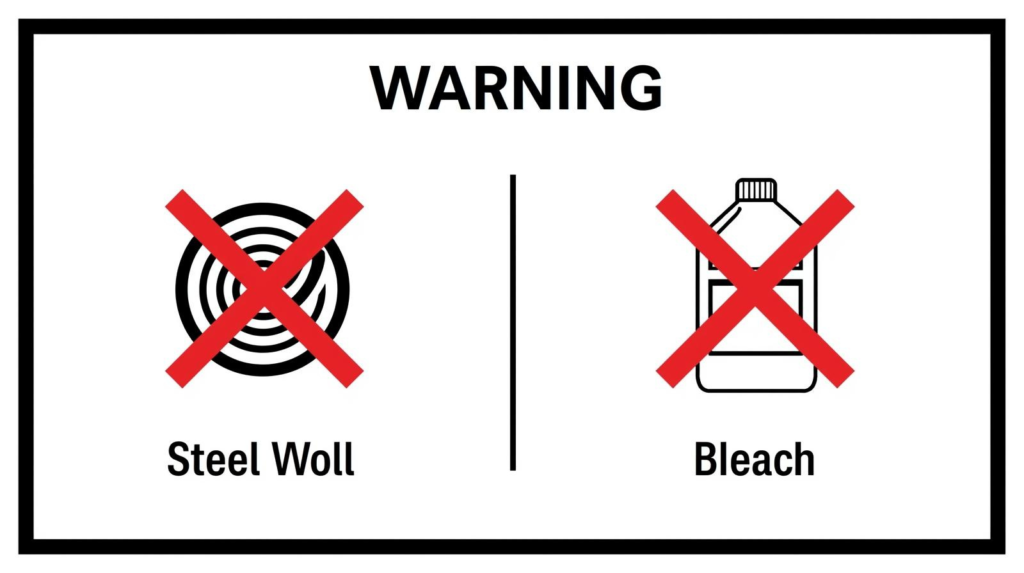

- No steel wool/carbon-steel brushes: they can leave iron particles that cause more rust. (Nickel Institute: avoid ordinary steel wool/brushes, World Stainless: steel wool can leave rusty stains, and manufacturer-style guidance like “Do not use steel wool… can leave iron particles”.)

- Avoid chloride/bleach-type cleaners on stainless: chlorides can stain/pit stainless and worsen corrosion. (BSSA: chlorides/hypochlorite bleaches can cause staining & pitting, plus “do not use cleaners containing chlorides” guidance in commercial stainless cleaning sheets.)

- Never mix bleach with acids (like vinegar/citric acid): it can release dangerous gas. (CDC: never mix household bleach with other cleaners, and safety warnings from Poison Control about bleach + acid.)

Step 1: Confirm it’s rust (not baked-on food or discoloration)

- Rust is typically orange/brown spotting or streaks that feel slightly rough.

- Heat tint (blue/gold) on cookware is different and may need a different approach than rust (industrial cleaning guides distinguish these processes and recommend starting mild). (Nickel Institute cleaning guidance: start with the mildest method, and general care notes like AZoM’s stainless cleaning overview.)

Step 2: Start with the gentlest method (works for light surface rust)

Option A: Baking soda paste (good first try)

- Wash the area with mild soap and water; rinse.

- Make a paste of baking soda + a little water.

- Apply the paste and rub gently with a soft cloth or non-scratch sponge in the direction of the grain.

- Rinse thoroughly and dry completely.

This approach is specifically recommended for “surface rust” by appliance makers. (See GE Appliances: baking soda paste for surface rust and the general “rub with the polish lines” advice in the Nickel Institute guide.)

Option B: Mild abrasive cleanser (non-chloride) + soft pad

If baking soda isn’t enough, use a mild non-scratching abrasive powder (non-chloride) with warm water and a soft cloth/sponge—again, rub with the grain. (Nickel Institute: mild non-scratching powders + rub with grain, and “avoid chlorides” reminders in stainless care sheets like this cleaning bulletin.)

Step 3: For stubborn rust spots, use an oxalic-acid cleaner (very effective)

Oxalic acid is commonly recommended for rust staining on stainless—often sold as products like Bar Keepers Friend. (See GE: oxalic-acid cleaners for oxidized stains/surface rust and Bar Keepers Friend instructions for rust stains on stainless steel.)

How to use (typical best practice):

- Wet the surface.

- Apply the cleaner with a damp soft cloth/non-scratch sponge.

- Rub lightly with the grain.

- Do not let it sit too long (many product instructions warn against extended dwell time).

- Rinse very well and dry.

(See “rub with polish lines” in the Nickel Institute guide and dwell-time cautions in Bar Keepers Friend’s guidance.)

Step 4: Rinse, dry, and let the surface re-passivate

This part matters more than people think:

- Rinse thoroughly to remove cleaner residue.

- Dry immediately to prevent water spots and reduce corrosion risk.

- Leaving the surface clean and exposed to air helps the protective film reform (natural passivation). (BSSA: stainless steels self-passivate when clean and exposed to oxygen, and practical “rinse thoroughly + wipe dry” guidance in stainless cleaning sheets like this bulletin.)

Step 5: If rust keeps coming back, remove the cause

Recurring rust on stainless is usually a contamination or environment issue:

- Stop using steel wool or carbon-steel tools nearby (they shed iron). (World Stainless warning on steel wool leaving rusty stains, Nickel Institute: avoid ordinary steel wool/brushes.)

- Avoid chloride cleaners (including some bathroom/mortar cleaners and bleach-based products). (BSSA: chloride solutions can stain/pit stainless, plus “do not use chlorides” reminders in stainless cleaning sheets.)

- Rinse and dry after exposure to salt, harsh cleaners, or standing water, especially in humid kitchens/bathrooms (maintenance guidance commonly emphasizes rinse/dry steps). (AZoM cleaning overview: wash/rinse/dry improves results, and “rinse thoroughly + wipe dry” in stainless cleaning bulletins.)

When DIY ends: pitting, deep rust, or “tea staining” everywhere

If you have pitting (tiny craters) or widespread staining that returns quickly, you may be dealing with more serious corrosion conditions or surface damage. Industrial practice uses controlled “pickling/passivation” processes for certain corrosion issues, but those chemicals are not a casual home DIY project. (See discussion of passivation/pickling differences and standards context in passivation explanations like this ASTM A967 explainer and general passivation basics like BSSA’s passivation article.)

Summary

- Start mild (soap + baking soda paste).

- Escalate to a non-chloride mild abrasive, rubbing with the grain.

- Use an oxalic-acid cleaner for stubborn rust, then rinse and dry thoroughly.

- Prevent recurrence by avoiding steel wool and chloride/bleach cleaners, and by drying stainless after cleaning or splashes.